Customer Services

Copyright © 2025 Desertcart Holdings Limited

Full description not available

G**R

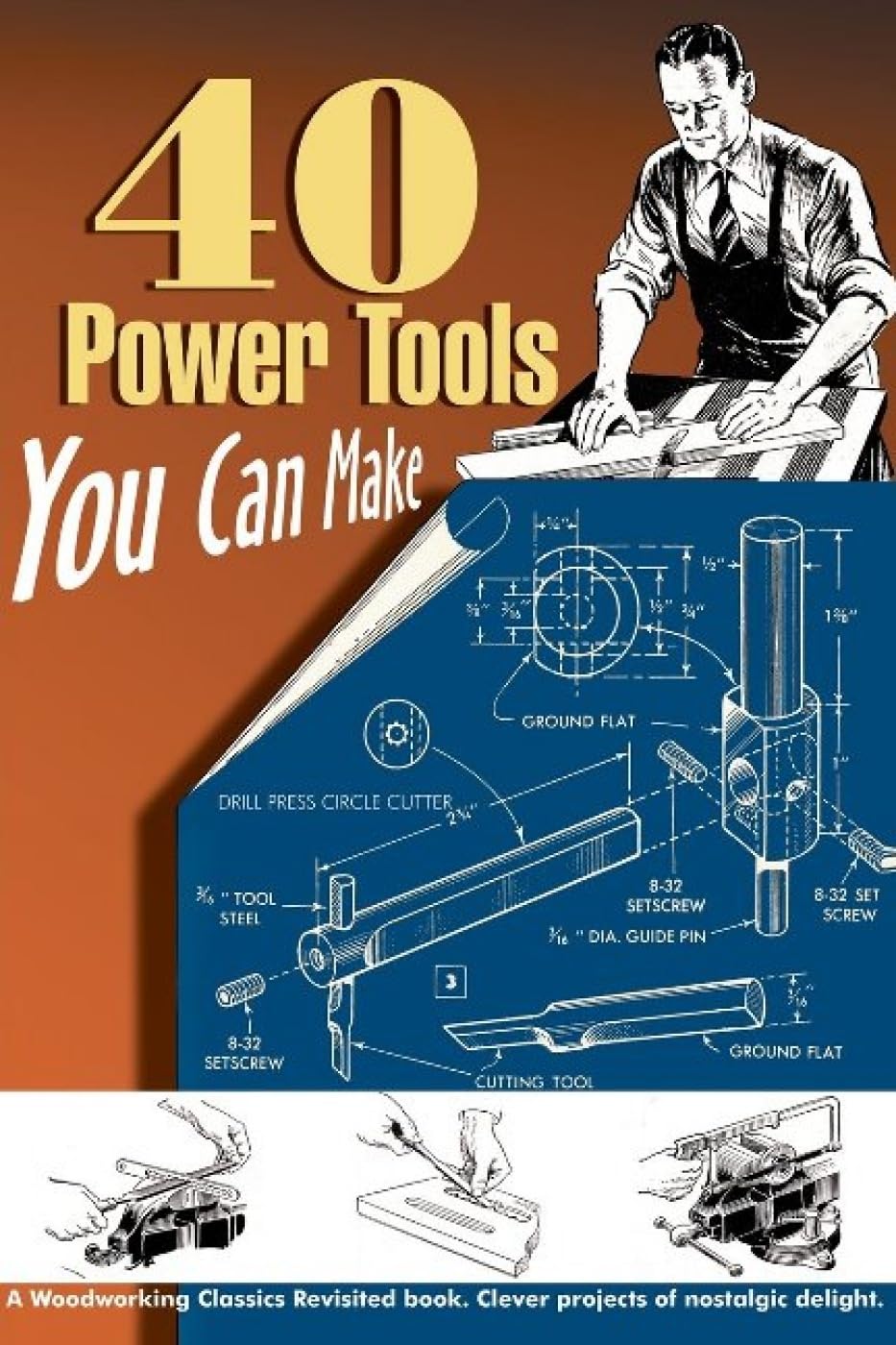

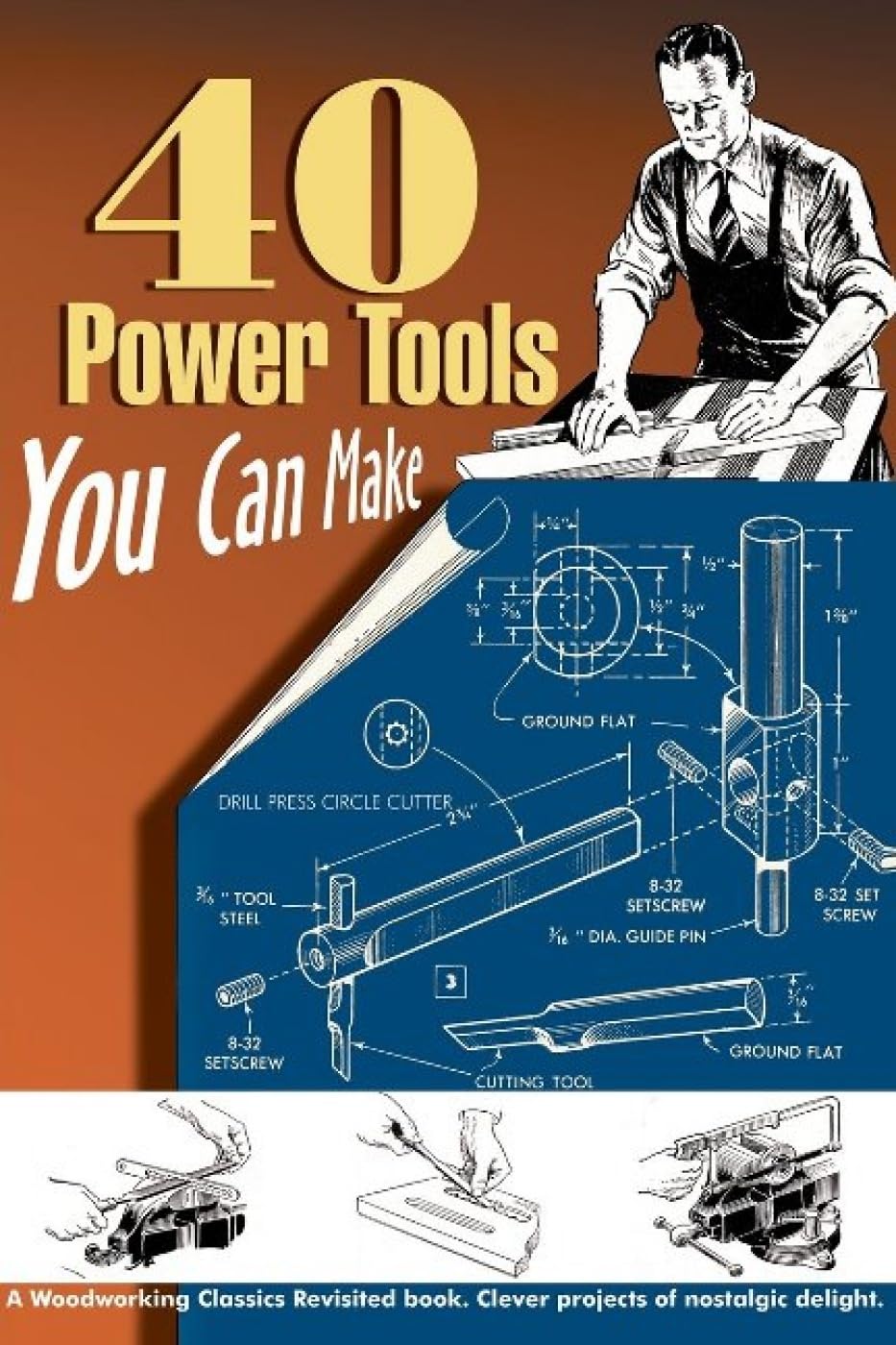

Fab Fifties style, still relevant and useful

Many woodworkers enjoy designing and making jigs for power or hand-tools. Some of us make our own hand-tools too: chisels, planes, saws, chamfer-cutters, beading / vining cutters, shooting boards, spoke-shaves etc...But how many woodworkers ever consider making their own powered shop tools?My father, who was born in 1898, was a pattern-maker and stringed-instrument repairman. He lived through the Great Depression and understood the value of making things himself. That included making MOST of his own tools. He had this book which I read and re-read many times. We both used it as a reference to construct table-saws, band-saws, (including a horizontal re-sawing band-saw) three different thickness-sanders, a frame-saw and numerous other smaller projects.The illustrations are black-and-white and hand-drawn by real old-school draftsmen. Although the book is small, it is edifying and inspiring! The diagrams and "blue-prints" are easy-to-read. There are a few dimensioning errors, but they are small and of little significance because you probably will never use the designs exactly as they are here. Most of the time, we cash-strapped woodworkers use spare parts to make our own tools: salvaged motors, bearings, lifts, pulleys, wheels, raceways... so we never followed these dimensions exactly.Prices and specifications have changed dramatically since this book was published. The common sense and practical advice in this book is timeless though. Even if you never build any of the machines herein, you will get a kick out of the funky-fifties retro style. At least, I do, though that may be a reflection on my vintage!There are complete plans for every machine listed in the contents. If you do decide to tackle one of these projects, you will undoubtedly need to change specifications to suit your motors, available bearings, hardware and other materials.Trust me... making your own tools is practical and not nearly as hard as you might think. In many cases, you can make power tools that are BETTER than commercial models, especially if you are making them for specific applications.Commercial tools are built for maximum versatility. You always have to pay for MORE than you need to get the few features you actually want. There are often quality or design compromises with commercial tools.For instance, to get an accurate commercial thickness sander with decent dust collection, you have to pay several thousand dollars for an industrial-quality machine that requires 3-phase power and a large commercial dust collection system. Not only does this bloat your budget for the machine, but you have to pay for rewiring to code, get inspections and a licensed contractor, AND buy an expensive dust-collection system.A luthier (who makes or repairs stringed instruments) needs superb accuracy and dust collection in a thickness sander, but he rarely can justify the cost or real-estate commercial machines usurp. He does NOT need to sand large sheets of wood, so why pay for the extra weight and size of commercial machines? Making a home-made thickness sander is a simple and practical solution! You can build a machine to suit the size of your shop, your projects and your budget!Another example: Table saws...Table saws come in two basic types: small portable contractor saws and large stationary "cabinet" models. There's a huge variation in cost and cheap saws are often riddled with design compromises and manufacturing flaws. That's because manufacturers want increased profits by reducing cost, yet they must include features for a wide variety of uses. Construction workers, Cabinet makers, hobbyists and professional luthiers have different needs, so the good saws always include superfluous features. That is never the case with your own design. Why pay for things you don't need?I have even seen home-made table saws that are human powered by treadle or bicycle-type mechanisms! Try finding a commercially made leg-powered saw! This could be a very attractive idea for those interested in a "green" lifestyle. The ONLY way you can get one is to MAKE IT FOR YOURSELF. This book does not show specific examples of human powered tools, however the information it contains can easily be adapted for that purpose.This book is LOADED with practical advice for metal working and welding too! I do not like to weld. Neither did my dad. This book helped us both with practical advice and examples, making that work safer and easier.Another important thing you can get from this book even if you don't build anything from it: reading it imparts a better understanding of how power-tools work. When you see the inside of these machines, learn which parts are crucial and how they can be adjusted, you can operate ANY power-tool more accurately, safely and efficiently. This book will help you understand your machines better, and THAT will make you a better woodworker.Even though I have only made a few of the machines herein, it has been tremendously useful. I love this book and am going to order another copy to replace the dog-eared one my dad had. If you have any interest in power-tools, (to build, buy, collect or use...) you will enjoy this quirky yet sensible retro tome.You CAN build your own power tools.You CAN make them inexpensively.You CAN make them BETTER than most commercial tools for specific uses.This book will help in many ways with practical advice and instructions; but mostly... it's just FUN !

A**L

Fun but Impractical

Projects are complex and many of them require machinist knowledge. I do not think the average woodworker would want to construct any of these projects; however, there are many excellent ideas contained in this project book. For the most part, the drawings are clear, however, somewhat small. The explanations concerning how to build the project where much too short. Thus, the book is fun to review, but has little in the way of practical application.AD2

D**N

Fairly dated material

This was probably spectacular in 1950. Today it is a good read for background information and to stimulate thought on new ways to do things. If you look at it from the view of a mechanical engineer as opposed to electrical it is a great foundation. Although the material is dated it is sound principle. You can probably purchase all 40 items cheaper than building them. None the less it is informative and thought provoking for modification/repair/salvage of existing machines.

S**T

Dated but interesting

Many DIY tools in this book, however, most require an enormous amount of work and making difficult parts. Still, I did get some great ideas for a few projects. Black and white pictures and drawings.

S**9

Fun and interesting purchase

Just as described, it is a book about how tools were put together when resources were scarce and necessity was the mother of invention. If the projects were built as described, there would be safety issues but well worth reading through to see the ingenuity and resourcefulness of the plans. A good diversion reading book.

G**T

not exactly what I expected

I was not as good as expected but acceptable. a lot of the "build your own" is if you have access to machine tools.good for the craftsman who wants to build machinery as a hobby.

D**L

Five Stars

Bought as gift.

S**G

Very happy he ordered

Husband found the book impressive. Very happy he ordered.

V**C

Interessantissimo

Anche se non recente, offre tuttora molti spunti interessanti ed anche le macchine proposte, seppur di non sempre semplice realizzazione, coprono numerose esigenze.

S**I

Gutes Buch

Interessantes Buch, schnelle Lieferung, nett um ein paar Ideen zu sammeln. Nur wenn man wirklich was nachbauen will muss man halt auf metrische Maasse umrechnen

Trustpilot

3 weeks ago

1 month ago