Customer Services

Copyright © 2025 Desertcart Holdings Limited

Desert Online General Trading LLC

Dubai, United Arab Emirates

🔧 Measure with Confidence, Adjust with Ease!

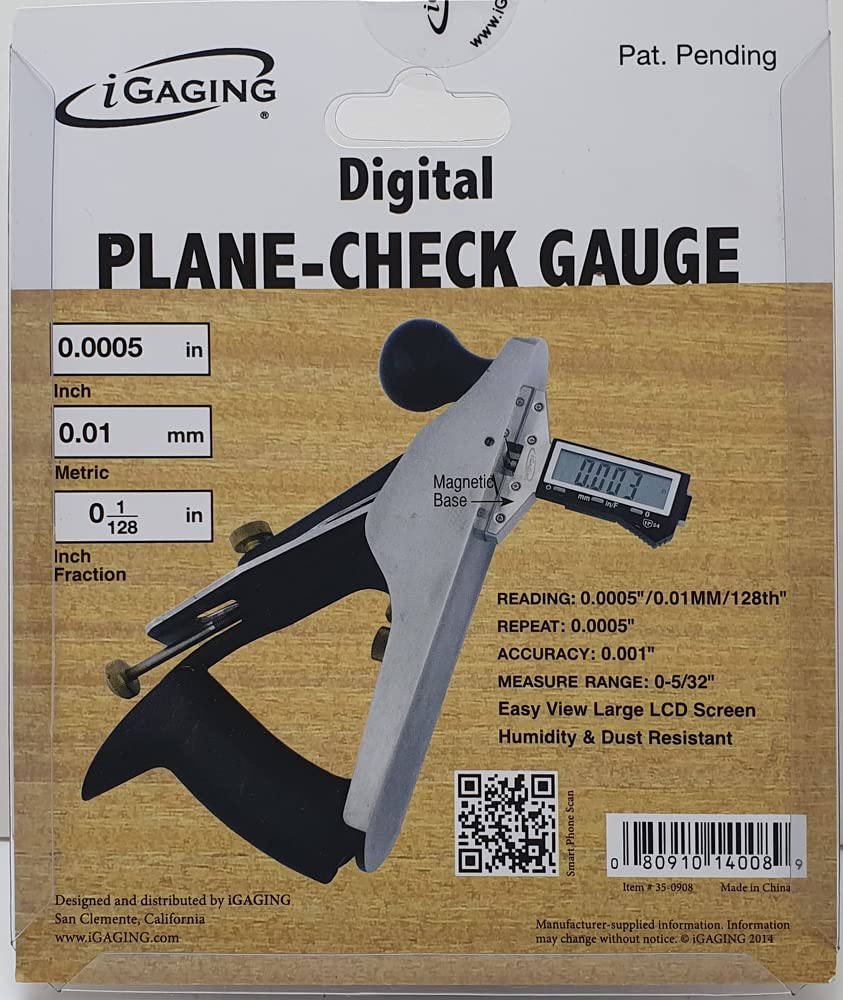

The 35-0908 Igaging Digital Plane Setting Gauge is a precision tool designed for accurate plane iron adjustments, featuring a measuring range of 0-5/32. With its magnetic base for secure attachment to metal surfaces and included batteries, this lightweight gauge is perfect for professionals seeking efficiency and reliability in their work.

| Manufacturer | Igaging |

| Part Number | 35-0908 |

| Package Dimensions | 15.01 x 12.4 x 3.91 cm; 82 g |

| Batteries | 2 CR2 batteries required. (included) |

| Item model number | 35-0908 |

| Style | Classic |

| Material | Metal |

| Power Source | Battery Powered |

| Item Package Quantity | 1 |

| Included Components | Hand Planer |

| Batteries included? | Yes |

| Batteries Required? | Yes |

| Item Weight | 82 g |

O**Z

extremadamente mala

he comprado no uno ni 2 medidores igagin y son verdaderamente de buena calidad, este es el primer producto que sinceramente no lo regreso porque no tengo tiempo de ir a la paqueteria, pero es sumamente inutil su funcionamiento escuche comentarios pero como casi siempre dejo de lado los comentarios y prefiero probar el producto y siempre me habia funcionado despues de ver como gente reclamaba por doquier mientras que yo casi nunca, pero esta vez si fue la excepcion, lo mismo que logras a puro calculo con el ojo lo haces con este dispositivo con la diferencia que tardaras mas de 10 veces y jamas quedara parejo puesto que cuando alineas segun esto la navaja queda con la misma altura mas no con el mismo angulo ya que la navaja tiende a irse muchas veces de lado al realizar el ajuste aun sean milesimas por tal motivo jamas quedara exactamente con la misma medida de un lado que del otro sino me crees es muy simple compruebalo por ti mismo y veras que cuando lo tengas recordaras muy probablemente esto, no se necesita ni siquiera ser un muy buen ebanista para esto, pense me ayudaria como todos los productos igagin que he adquirido pero este desafortunadamente fue la excepcion...

D**E

Very simple, good value and it works

I got one of these sweet little gauge for Christmas from my wife, well, it was on my wish list, and I love it.First of all, I was very excited that my planes were set up very well with little deviance between the left to right measurement of my planes and all of them were very close in depth of cut. It's nice to know that your setup routines are consistent ... the only problem is that every time I stropped my blades, pulled them to clean the edge of pitch, etc. I had to go through a long, painstaking process to get them back to that point.I was able to reset my blade in both depth and consistency across the base in about 1/10th the time with this tool.It's going to be a huge time saver!

D**N

Great tool

Easy to use - accurate - foolproof. I have never been able to get my hand plane blades dead on even across the mouth. My vision? who knows. This little gadget makes that a thing of the past. Try it - you'll like it. Plus - it only takes about a minute use.

D**R

Maybe good for jointer blades

Seems good quality for the price. I honestly thought i would use it but yeah i haven’t. I just set my plane blade on-top of my wood and advanced ot. Completely unneeded. Might work well for jointer blades but not so much a hand plane. Dang you stumpy nubs woodworking

L**E

006 inch for fine work, and the gauge repeatablility of +/- 0

The gauge itself exhibits lateral "play" in the stem that moves up/down, and the resolution of the readout is on the order of 0.001 inch because of this. Typically, the protrusion of the hand plane iron (blade) from the sole of the plane is on the order of 0.003 - 0.006 inch for fine work, and the gauge repeatablility of +/- 0.001 tends to be a "large" fraction of the desired setpoint. I have found that a functional and consistent methodology is to place the gauge stem "downstream" of the plane iron (e.g., behind the blade), with the magnetic "bridge" straddling the protruding blade, and then zeroing the gauge readout. I then slide the gauge forward and allow the stem to ride the taper of the blade until the stem is centered on the blade edge. I then record the reading. Repeating this procedure at the left and right ends as well as the middle of the blade provides the most consistent indication of blade protrusion across the plane. And so, although the gauge is functional, I would have preferred if the gauge stem exhibited less lateral "slop" which perhaps would eliminate the need to zero the readout prior to taking each reading.

Trustpilot

1 week ago

3 weeks ago