Customer Services

Copyright © 2025 Desertcart Holdings Limited

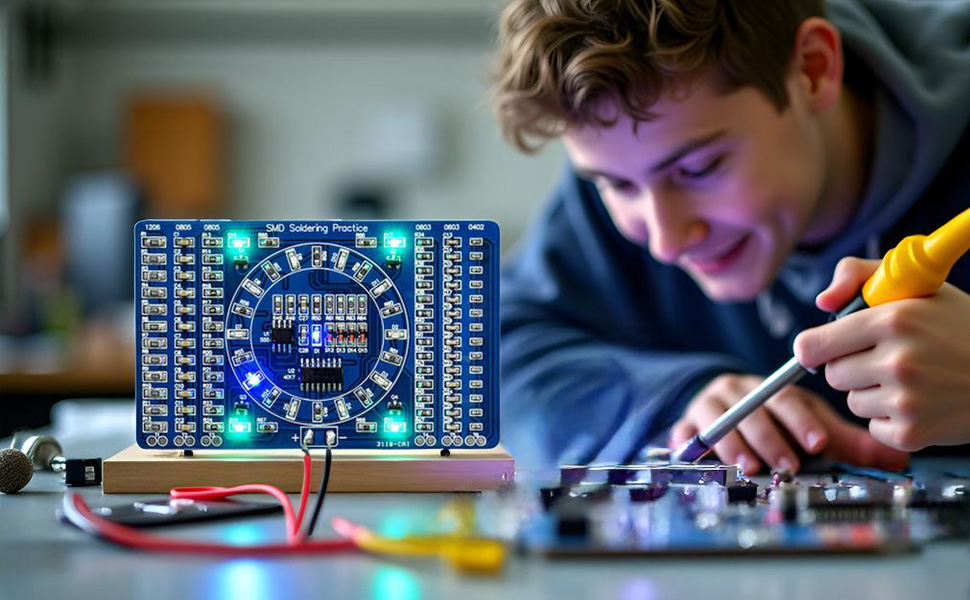

⚡ Light up your soldering skills with every connection!

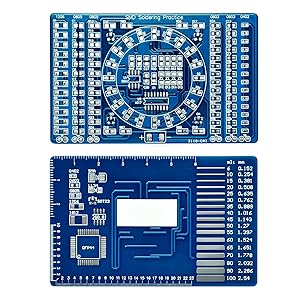

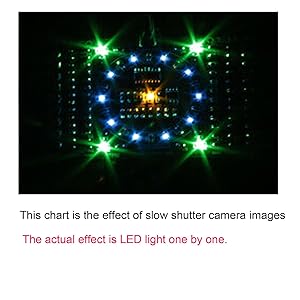

The Gikfun EK7028 is a compact, high-quality SMD/SMT soldering practice board designed for beginners. Featuring a clear mm/Inch ruler and marked components, it allows users to power the circuit (3-12V) to instantly verify soldering quality through a vibrant water lamp effect. This training tool enhances hands-on electronics skills with a detailed user guide and precision design.

| Screen Resolution | 3840 x 2160 |

| Max Screen Resolution | 3840x2160 |

| Chipset Brand | Intel |

| Card Description | Dedicated |

| Brand | Gikfun |

| Series | Ek7028 |

| Item model number | LYSB00VWB8F8K-ELECTRNCS |

| Item Weight | 0.32 ounces |

| Product Dimensions | 5 x 3.2 x 0.1 inches |

| Item Dimensions LxWxH | 5 x 3.2 x 0.1 inches |

| Color | Blue |

| Processor Brand | Intel or AMD |

| Number of Processors | 4 |

| Computer Memory Type | DDR4 SDRAM |

| Hard Drive Interface | Serial ATA |

Z**R

Instructions are a bit confusing, but I'm glad I bought this

The education value that you can get from this product for soldering and electronics is amazing, especially for such a cheap price. It really helped me understand how to micro-solder and how to get used to using a rework station. I got the whole thing to work perfectly and I'm very pleased with this product.My biggest criticism is that the instructions are a bit unclear and not really geared for beginners. Somebody who is buying this product is likely not just practicing how to solder these micro components, but also learning how to identify each one. I eventually figured everything out with very careful reading, but I do wish the included instructions clarified a lot of those things for beginners.

R**.

Wonderful kit for experienced electronics buffs looking to move up to SMD components

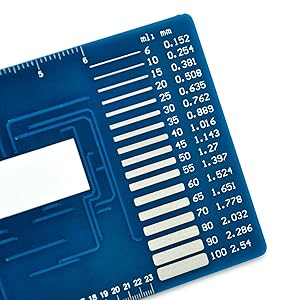

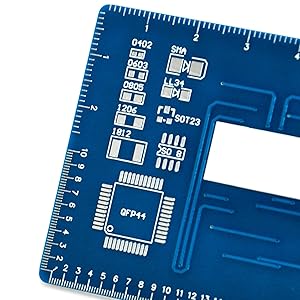

Provides all parts needed to construct the kit, plus spares of the most fragile and losable parts. Includes instructions in English; however, they're somewhat cursory, neglecting to mention the needed power supply (9 volts, supply your own connector) and providing little detail as to which parts go where. (You can figure this out from the bill of materials, which does not provide component markings, but does indicate how many are needed and the size of the component. Some logic is required, as the capacitors are unmarked.)This isn't a beginner kit.However, if you already know how to use your soldering iron with through-hole components, you are familiar with electronics in general, and you want to learn about SMDs and practice soldering them, this is a very good kit for the experienced hobbyist. To succeed, you are going to need the proper tools, which obviously aren't included: A soldering iron with a very fine tip, appropriate solder (eutectic lead strongly recommended), a good set of very fine tweezers, and good magnification—preferably a stereo microscope. That's the price of entry for hand-soldering SMD components.The kit includes a number of resistors and capacitors in 1206, 0805, 0603, and 0402 sizes. The 0402 capacitors are about the size of deer tick nymphs—large grains of sand. You start by soldering rows of components, from the larger size on down, gaining skill and confidence as you go. You can then move on to using those techniques to build the light-flasher circuit in the center of the board, which uses a 555 timer and a 4017 decade counter. The center-circuit components include LEDs, transistors, and glass diodes.The reverse of the circuit board includes a handy reference, including SMD component and pad sizes, circuit trace widths, and rulers.I found this kit to be vastly superior to Elenco's SMD kit in terms of helping me master the techniques needed to hand-solder SMD components.

R**W

Great Kit to Improve Soldering Skills

The media could not be loaded. Gave it a 4/5 just because the instructions were a little unclear. It would have been nice if the parts matched the instructions. That aside, this is a great kit if you want to practice your surface mount soldering. What I like about it is how it gets progressively harder as you begin to mount the other resistors and capacitors. The repetitiveness really helps you build up your hand-eye coordination and motor skills. By the end, you should feel very comfortable soldering. I would suggest using a microscope to complete this, as doing it by eye may be challenging

M**I

Brilliant

I've been soldering through hole parts for many years, thinking that SMD was best left to factories with specialized equipment. Working through this kit made me realize that soldering SMD by hand is not only feasible, but actually faster and easier than through hole in my newly-formed opinion.Completing this project was fun and meditative and now I have confidence in this skill and am eager to apply it to a project.The kit has a smart design. Your first 78 parts have no real penalty for mistakes because they are not part of the final "light show" circuit. Yet there are still some basic test points for these areas so you can check your connections with a multimeter. You start with 1206 size components (0.12 x 0.06 inches), then move to 0805, then 0603 and finally 0402. As you would expect, it gets progressively more challenging.After all of that practice, comes the LED blinking circuit. These are all 0805 components which should feel pretty manageable after finishing 0402. A schematic is provided but I never needed it - the board is already marked with what goes where, including the polarity of the LEDs and diodes. I did use the parts table to determine which part values to use. It's also useful to know how to read a SMD resistor code (e.g. 473 = 47,000 ohms).I experimented with a number of different techniques and tools and suggest you do the same, below is a small account of my experiences:Soldering Iron vs Paste + Heat Gun. Between these, I preferred a soldering iron with a small chisel tip.For the paste I was putting it on with a syringe and trying to fix it up with a toothpick - it looked a bit sloppy. For the larger components, it all worked reliably and components "magically" flowed into place. At 0603, about a third of the parts didn't settle correctly and needed corrections with the tweezers and heat gun. At 0402, about half of the parts needed corrections. I think that a solder mask and reflow oven would be quite a different (better) experience here but I don't have either of those.For the soldering iron, I prepped the area with rosin fluid (Kester 951) and held the component in place with some high-quality tweezers. I put a very small amount of solder on the tip and touched the pad, then the corner of the component for less than a second each. I never needed to use the solder wire directly on the board, which is great because I was already using both hands. After doing one side, I put down the tweezers, rotated the board and did the other side in the same way (touch the pad, touch the component side, done). I then went back to the first side and touched it with the soldering iron for another second or so for a finishing step. It takes longer to type this than to actually do it. You can also batch the work by doing one side of a bunch of components, then doing the other side in a followup pass.USB microscope vs headband magnifier (Donegan DA-4). They both worked but I preferred the headband magnifier for several reasons. In short, the headband magnifier was more comfortable to use, the "real" 3D image was nicer than the 2D LCD image and it was nice to easily see where my tools were as I worked. I found the 2x magnification on the magnifier was plenty enough for every case except the 0402, where a little more would be nicer.Silicone work pad. I recommend using one because these pads are heat resistant, and make it easy to see the tiny SMD parts. I placed the board right on the work pad while soldering. This allowed me to use the table to support my hands and keep them more steady during the work.Multimeter. My multimeters will light up an LED in the continuity testing mode. I used this to spot check the LEDs as I installed them, placing the negative probe on the "-" pad at the bottom center of the board and the positive probe on the resistor that is associated with the LED. The correct resistor can be discovered using the multimeter or by looking at the traces under the soldering mask.

K**N

Great practice but it's very much not a beginners piece

Great practice but it's very much not a beginners piece. Before starting this you'll want a super fine tip soldering iron. Also the instructions didn't tell you which resistors when in each location so it's like you get a puzzle to figure out while you're learning to solder small components. I guess that's a plus. I'm not sure if the lights are supposed to all light up at once or move around in a circle but mine light up at the same time. Another big thing is it didn't come with anything to connect power to it. I had a spare 9v battery connector that I used. Might want to pick one of those up with this. I'll post a picture of how I have mine arranged later.

Trustpilot

2 weeks ago

4 days ago